Advantages and characteristics

usage scenario

Dynamic gold lithographic solutions

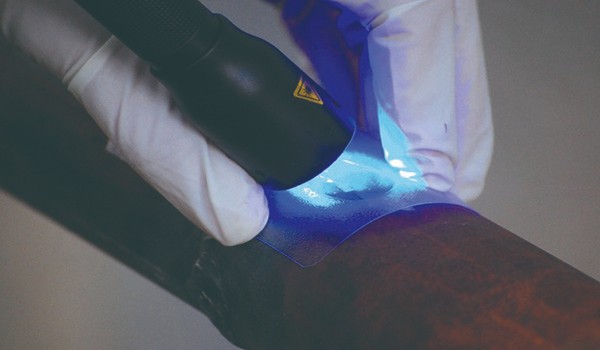

Technovit 2200 series: Microstructure imprints for surface analysis, quality assurance, easy handling, fast curing with blue light.

Advantages and characteristics

| Easy to use: The light-cured material is applied directly to the relevant position (spatula, brush or syringe) and cured within 20-60 seconds by a special blue light. Not damaged by temperature effects: operating reliably even at very low and very high temperatures without any mass loss. Compatible with all blue light sources: All products of the Technovit 2200 series can be cured using Pekalux POWER LED or Technovit Blue LED. If thicker layers of thickness (greater than 4 mm) are required, this must be done in several layers. For this purpose, the smear layer formed on the polymeric surface is required as an "adhesive", and each layer must be cured separately. All the products of the Technovit 2200 series can be combined with each other and can be further mechanically processed by grinding and polishing as usual. |

usage scenario

| Microcracks and holes filling the ground part Fixed minimum (electronic) components Small parts packaging Stable corrosion layer Mechanical machining stability Apply the protective layer before embedding and preparation Microstructure impression roughness measurement Determination of contour Microstructural imprinting (is a more meaningful document than a photo) |

Dynamic gold lithographic solutions

| Using the Technovit 2200 series, microstructural impressions can be obtained directly from the components in a non-destructive manner, then processed in the laboratory and evaluated under an optical or scanning electron microscope. Even special "problem cases" in material graphy can be easily solved. The mold was taken using Technovit 2210 1. Apply Technovit 2210 on the clean surface. 2. Polymerize with Technovit Blue LED for 40s. 3. Remove the hardened impressions from the surface. Prepare for the tactile measurements. |

Technical Data Technovit 2200 series

product name | characteristic | application area |

Technovit 2200 | Low-viscosity, transparent liquid | Stabilize multilayer holes or sensitive components before cutting |

Technovit 2210 | Medium viscosity paste, cream color | Surface stamping, visual and tactile assessment, fixation assistance of fragile samples or edge protection |

Technovit 2220 | Medium-viscosity liquid, blue or clear | Microstructure imprint, 10u imprint accuracy |

TOP