Complete varieties, suitable for all application fields

Does not contain hazardous substances

Strong liquidity

Short curing time

Technovit Brands include a large number of different technical polymers, which are developed mainly for the purpose of testing materials. In addition to traditional materials science applications, Technovit products are used in industrial production proc

Technovit® 4000(The low-shrinkage)

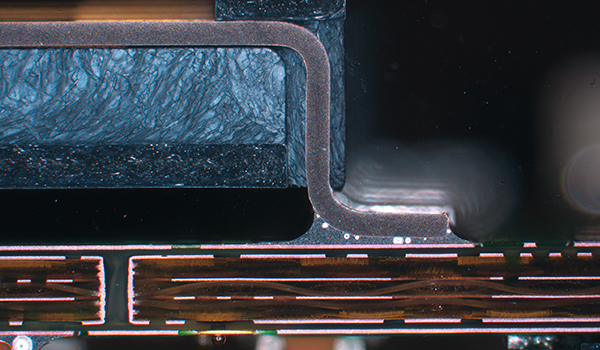

| Technovit 4000 is a fast-curing, cold-polymerizing, 3-component resin for optimum edge protection and marginal sharpness also ideal for embedding samples with porous surfaces, small gaps, blind holes or undercuts. very low polymerization shrinkage and optimum margin fit excellent flow behavior very good adhesion to metal surfaces, therefore optimal edge protection and marginal sharpness excellent grinding and polishing properties excellent grinding and polishing properties |

Technovit® 4006(High Clear)

| Technovit 4006 - The crystal-clear version for sensitive samples. The highly transparent 2-component cold embedding resin allows a lower temperature load due to the longer curing time. Thus target preparations are also possible on more sensitive materials – easy and straightforward! 2-component powder-liquid system easiest application due to variable mixing ratio low-gap embedding due to integrated bonding agent and lower temperature load good grinding and polishing properties new initiator system – less irritating! ideal for routine target preparations with lower temperature load |

Technovit® 4071(The universal)

| Technovit 4071 - Uncomplicated and ideal for all routine embeddings. The highly cross-linked Technovit 4071 provides the best grinding properties combined with easy processing. The semi-transparency allows good orientation and the short curing time makes it indispensable for routine embedding. Series of samples can be produced in a very short time. easy handling, best for routine work low viscosity short curing time (5–7 min.) very good grindability, mechanically workable fast routine embedding resin for the entire range of materials |

Technovit® 5000(The conductive)

| Technovit 5000 – enables conductive embeddings, perfect for SEM examinations and is also a good basis for the electrolytic preparation of metallographic samples. This 2-component, copper-based cold embedding resin enables conductive embeddings that are ideal for SEM examinations. Technovit 5000 is also a good basis for the electrolytic preparation of metallographic samples. conductive electrolytic sample preparation |

Technovit® 5071(The dissolvable)

| Technovit 5071 - for samples that have to be removed again. Technovit 5071 is very well suited for the embedding of samples that subsequently have to be removed in order to examine them under a scanning electron microscope, for example, or to prepare them electrolytically. Due to its good mechanical properties, Technovit 5071 is very suitable as an adhesive that may have to be removed again. Technovit 5071 enables the gentle removal of sensitive samples and thus all-round visibility during SEM examination. It provides the easiest application with very good mechanical machinability. chemically soluble (with acetone, dichloromethane or similar) thermally softenable (becomes soft from 150 °C, 30 min holding time) simplest application (variable mixing ratio 1:1 to 3:1) good adhesive properties |

Technovit® 7100(The cuttable)

| Technovit 7100 – cuttable embedding resin, ideal for microtomy. Whenever samples need to be embedded for cutting, Technovit 7100 is THE material of choice. Originally developed for histology, Technovit 7100 has also proven its worth in industry for many years due to its universal application possibilities. embedding and production of sections and thin sections down to 1 μm embedding of complex-shaped, fine plastic parts ensures optimal infiltration of porous materials no temperature load “cradle”-insert: the pointed shape distributes the cutting forces evenly and thus protects the blade and sample |

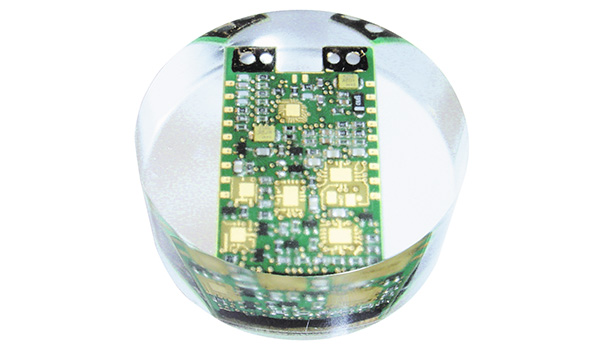

Technovit® EPOX

| Technovit EPOX – for transparent embedding without a temperature load. Technovit EPOX is an epoxy resin system consisting of a resin component Technovit Epox Resin and optionally with a fast hardener: Technovit Epox Hardener fast, or a slow hardener: Technovit Epox Hardener regular. The choice of hardener can influence the curing time, pot life and above all the temperature load. The pot life of approx. 1 hour favours, for example, the infiltration of porous materials – especially under a vacuum. Application under vacuum possible high transparency, good adhesion to the workpieces UV colour stable variable curing times, can be influenced individually gap-free |

Technical data Technovit Cold mosaic resin

model | type | apply |

Technovit 4000 | Bedge shape | seamless embedding of porous, multilayer structural metal samples |

Technovit 4002 | Bedge shape | Strapless embedding of the metal samples |

Technovit 4006 | Transparent type | Microscopic detection of temperature-sensitive materials and complex structures |

Technovit 4071 | Fast type | Daily buried products, almost suitable for all materials |

Technovit 5000 | conductivity type | SEM detection / electrolysis of the sample preparation |

Technovit 5071 | Soluble type | Sample samples need to be recovered due to value or confidentiality |

Technovit 7100 | special type | Microbial slices / fine polymer materials / textile paper / biological samples of the embedded resin |

Technovit EPOX | epoxy resin | Temperature sensitive materials / multimicroporous complex structures require vacuum permeable soft materials |

TOP