M-type single-crystal diamond polishing solution

P-type polycrystalline diamond polishing fluid

Emulsion-type diamond final throw-out polishing solution

Bio DIAMANT Series water-based environmental polishing solution follows the strict European REACH standards, achieve zero organic emission (VOC-Free) and biological friendly, very suitable for sample making laboratories, no need for special emission treat

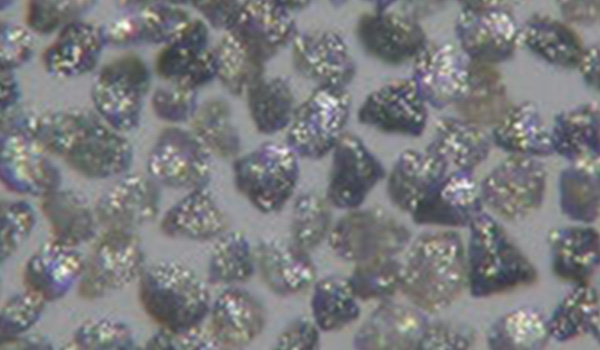

M-type single-crystal diamond polishing solution

| M-type single crystal diamond polishing solution has accurate particle size distribution, efficient polishing ability, easy color identification matching, can be used with the whole category of polishing fabric, is a very suitable variety for sample preparation laboratory. |

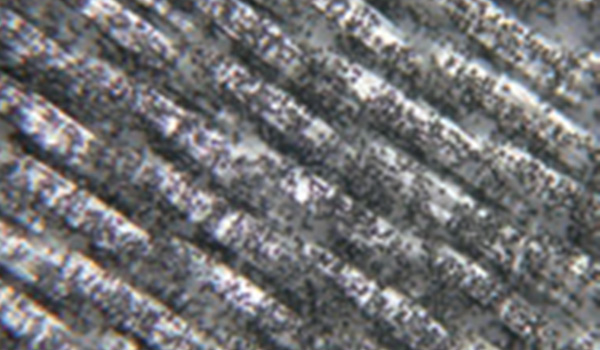

P-type polycrystalline diamond polishing fluid

| High quality polycrystalline structure with high density fabric can quickly improve the polishing efficiency and improve the flatness of the sample preparation surface. It is recommended to use with high density and strong support and high flatness polishing cloth. |

Emulsion-type diamond final throw-out polishing solution

| MM140 is an emulsion-based high concentration diamond final cast liquid, suitable for the end of all kinds of material samples, especially suitable for air oxidation and water corrosion sensitive sample material. |

Technical data Bio DIAMANT gold-phase polishing fluid

M-type single crystal highly efficient diamond abrasive suspension | |||

specifications | pigment | fineness | apply |

9MMe type | Red suspension | 9μm | Suitable for high / ultra high hardness material sample precast / initial throw |

6MMe type | Yellow suspension | 6μm | Suitable for high hardness / difficult to level off / toughness material sample pre-throw / first throw |

3MMe type | Green suspension | 3μm | Suitable for perfect edge preservation / preservation inclusion, need excellent flat surface of the initial throw |

1MMe type | Blue suspension | 1μm | Suitable for high hardness / difficult to level off / tough material sample finally cast |

¼MMe mould | Gray suspension | ¼μm | Suitable for the end of medium hardness |

P-type polycrystalline fast dispersed diamond abrasive suspension | |||

specifications | pigment | fineness | apply |

3MMe type | Black suspension | 3μm | Suitable for high / ultra high hardness material sample precast / initial throw |

1MMe type | Black suspension | 1μm | Suitable for high hardness / difficult leveling / toughness material sample |

Polishing fluid application of small knowledge

It is recommended to use 2 TS type 3 polishing cloth + 3um polycrystalline polishing solution for the initial throwing of soft materials, which can level the sample surface faster.

Using 2 TS type 3 polishing cloth + 1um polycrystalline polishing solution can improve the smoothness of the observation surface.

method of operation

The first step is to moisten the surface of the polishing cloth with water. In order to integrate the abrasive into the designated position of the polishing cloth as soon as possible, pay attention that there must be a drying action after wetting.

The second step is to add or spray the polishing solution to the position where the sample passes, and add the same position in the subsequent polishing.

The third step, can regularly to the polishing position add MM702 polishing lubricant to ensure cooling and lubrication effect, because the consumption of abrasive in the polishing process is very slow, even if the dry polishing cloth, drip with special polishing lubricant can activate most of the polishing cloth containing abrasive, which is why polishing cloth and abrasive is one to one collocation, no need to often cleaning and not mix.

MM702 is a special dispersion diluent designed for water-based polishing solution. The optimized dispersion system can be used to activate the diamond abrasive accumulated in the polishing cloth and provide excellent cooling and lubrication function for the polishing process. It is suitable for polishing cloth using diamond suspension or diamond polishing paste.

The fourth step, the polishing cloth can be cleaned with clean water or alcohol, recommended to use a special 742 detergent for cleaning, in order to better save, cleaning method:

1. Spray 742 detergent dilution evenly on the surface of the used polishing cloth and infiltrate for about 1 minute.

2. Start the working plate at low speed, open the water spray head, and move the plastic scraper from the inside out until the disc scraping changes from milky white to clear water.

TOP