Extend the life of cutter pieces and instruments

Excellent filtration

Environmental friendly

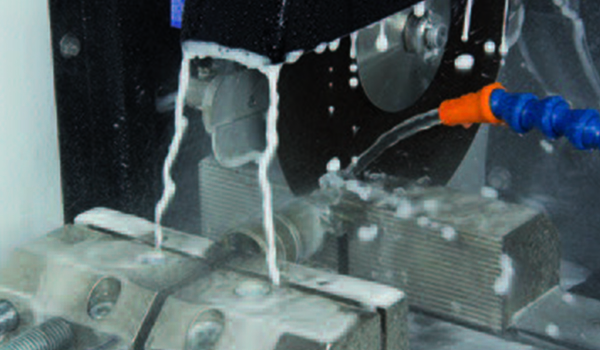

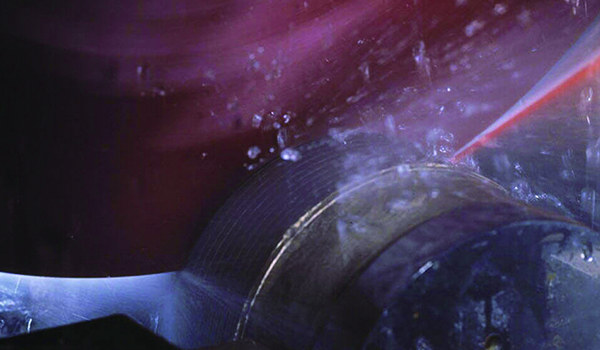

LAMPLAN Cutting coolant series is concentrated coolant, when use should be miscible with water. It has good lubrication and cooling effect, avoiding overheating, so that the microstructure of the metallographic material is not damaged during the cutting p

Extend the life of cutter pieces and instruments

| Cutting coolant contains lubricants that improve the quality of the cutting surface and extend the life of the cutting wheel; it also contains preservatives that prevent corrosion of parts and machines. The cutting coolant has a good flushing effect, which can keep the parts, the tongs and the machine clean, thus extending the service life of the machine. |

Excellent filtration

| Excellent filtration, because the fine particles can be quickly separated from the liquid. This coolant produced less foam and improved visibility in the cutting chamber. |

Environmental friendly

| No boron, chlorine, secondary amine, formaldehyde, and phenol-releasing agent. |

Technical data to cut the coolant

parameter type | data |

pack | 5 Lil |

surface | Yellow emulsion |

Density at 20℃ | 1.1 g / cubic cm 2 |

The PH values in use | 9.1 |

refraction coefficient | 1.4 |

Cutting in the application of small knowledge

1. A larger flange can better support the large cutting wheel to cope with a harder cutting material or reduce the cutting slope of the cutting soft material due to elasticity. Replacing the flange needs to consider the impact on the cutting ability: cutting diameter = (cutter diameter-flange diameter) / 2.

2. Using cutting coolant can effectively reduce the thermal damage and improve the cutting efficiency of cutting: coolant is by adjusting the proportion of water and lubricant to obtain different cooling lubrication ability, adjustable ratio between 1:25 to 1:10, when cutting material soft or heat sensitive material can appropriately increase the proportion of water, to get better cooling effect, when cutting hard material into the knife speed is slow, can increase the proportion of lubricant appropriately to get better lubrication effect.

3. Preparation method of cutting coolant: all the cutting coolant in the market is concentrated, which must be the order of adding water before adding concentrate and stirring evenly. This order determines the suspension structure of water wrapped in oil, so as to effectively adapt to the needs of cooling before lubrication in the cutting process.

4. When cutting, the coolant should be sprayed in the cutting part quickly, and the coolant should be replaced regularly. Generally, it is recommended to replace it once a month.

TOP