Largest cut-off area on the market of Ø 300 mm cut-off machines

Technical characteristics and equipment

Many cutting possibilities are offered

Easy to use

High security

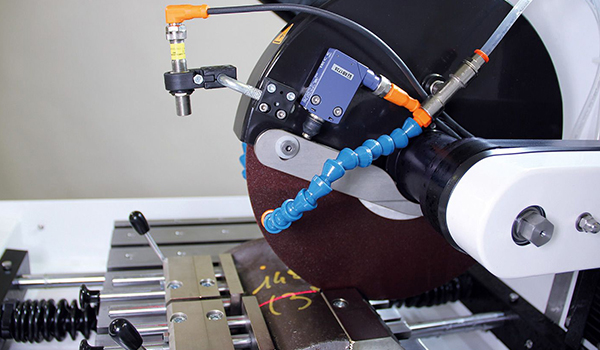

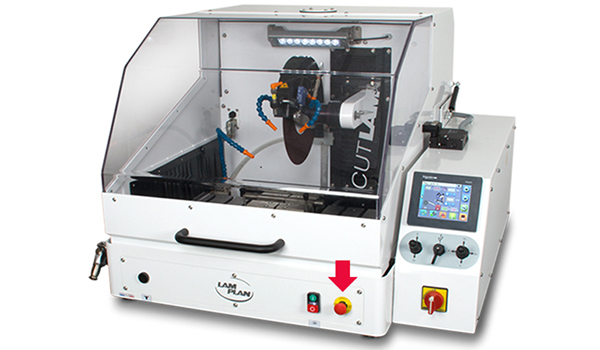

The CUTLAM 3.1 offers an unprecedented cutting capacity (Ø300 mm). Thanks to the wide range of movement options for the cutting disc and table, as well as the feed speed control system, there are no limits to their use.

Largest cut-off area on the market of Ø 300 mm cut-off machines

| The CUTLAM 3.1 offers an unprecedented cutting capacity, the machine table can move forward and backward automatically over a distance of 300 mm. New, the cut-off wheel has an automatic and linear top-to-bottom movement. With this linear movement, this new-generation of cutting machine offers a 140 mm space under the cutting wheel. The CUTLAM®3.1 has a cover which includes opening side to cut bars. |

Technical characteristics and equipment

| The maximum cutting capacity can reach 110mm high and 210mm long |

Many cutting possibilities are offered

| The rotation speed of the cutting wheel and the feed speed of the shaft can be programmed to prevent any deterioration or deformation of the sample. There are three cutting modes available: manual (through the joystick), semi-automatic, and automatic. The motion of an axis can be continuous or sequential.

CUTLAM 3.1 is also equipped with intelligent motion function: define acceptable torque for the cutting wheel, and the touch screen will automatically adjust the feed speed of the shaft.

This option can cut materials with different hardness (such as steel with HVOF coating) without changing the feed rate. This option allows for avoiding prolonged testing activities to define the correct feed rate. |

Easy to use

| The CUTLAM3.1 is extremely simple to operate with its large touch screen (5.7 inches) and intuitive interface. The 2 motorised axes of CUTLAM®3.1 (optional 3rd axis) can be controlled manually by two joysticks located near the control screen. The internal memory allow to save over 300 cutting programs, which can also be imported or exported via a USB port. |

High security

| An interlocking device maintains the cover in its closed position when the cutting wheel is rotating. When the cover is open, any axes movement (controlled by the joysticks) is only possible when the technician presses the "man present" button. |

Technical Data CUTLAM 3.1

Parameter Type | Data |

Wheel Ø | 250 to 300 mm |

Shaft Ø | 25,4 mm |

Max cutting capacity | Ø 110 mm |

Space between the cutting wheel and the table (with wheel Ø 300 mm) | 140 mm |

Table | Stainless steel 574 x 298 mm |

Longitudinal movement - table | 300 mm |

Vertical movement - wheel | 200 mm |

Transversal movement | 150 mm (optional) |

Motor power wheel | 3,8 kW |

Cooling/Lubrication | Recirculation system, 60 litres decantation tank, 2 chambers, Input 100 µm filter, 800 L/hour pump driven by the machine |

Wheel rotation speed | from 1000 to 4000 rpm |

Cutting mode | Manual, semi-automatic, automatic |

Feed speed control | from 0.1 to 20 mm/s, continuous or sequenced. Intelligent motion: automatic check of the feed motion according to the resulting torque on the cutting wheel motor |

Lighting | LED strip |

Protection | Cover secured by interlocking Man present button for operating the axes when the cover is open |

Voltage | 400 Volts - 50 Hz (three-phase + ground) |

Dim. W x H x D | 900 x 700 x 1000 (H. cover open 1100 mm) |

Weight | 210 kg |

TOP