High grinding efficiency

The sample preparation process is reproducible

Improve the efficiency of sample preparation

High flatness

The purpose of sample grinding in the metallographic sample is to remove the deformation layer and achieve a smooth and smooth observation surface, removing the deformation layer commonly known as thin, usually achieved by sandpaper. For high hardness sam

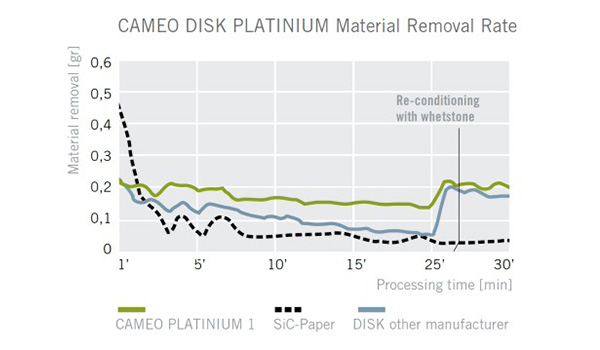

High grinding efficiency

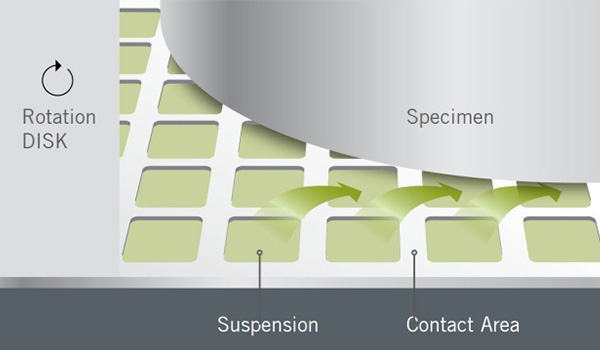

| The honeycomb structure of the diamond millstone was polished by reducing the contact area with the sample. Make the pressure required to grind the sample much less than that required when using flat disks. This reduces the risk of tearing of the grinding disc. |

The sample preparation process is reproducible

| With a specially designed honeycomb structure, the test lubricant can provide better circulation from one cavity to another. The evacuation of the wear residues ensures a constant grinding capacity, so the results are regular throughout the grinding and polishing steps. |

Improve the efficiency of sample preparation

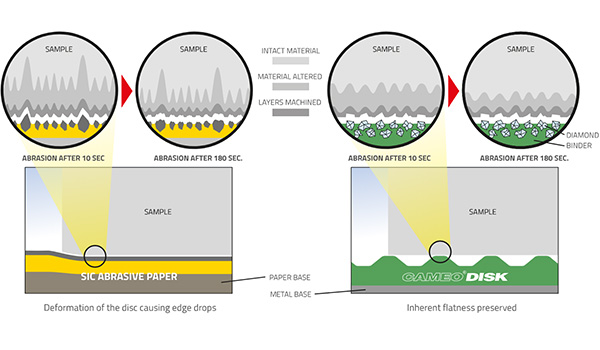

| Because the concentration of diamond powder particle size on the surface of diamond rough grinding plate is higher than that of traditional sandpaper, when grinding the sample, the new deformation layer introduced by itself is very thin compared with the sandpaper when removing the surface deformation layer produced by the cutting. There is no need to use different numbers of sandpaper to remove the local deep deformation layer introduced by the previous process, like sandpaper. |

High flatness

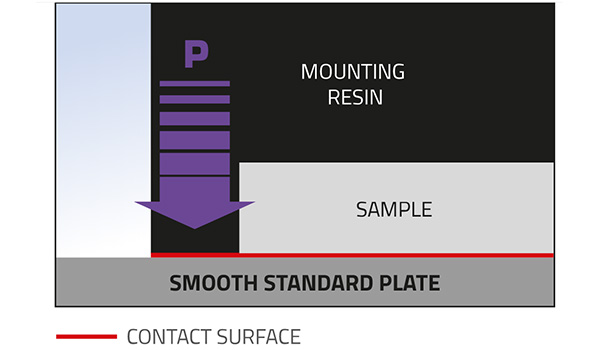

| The surface hardness of the diamond grinding plate is 400 HV, and the grinding plate itself will not appear local depression similar to sandpaper, which ensures the surface flatness of the sample and prevents the formation of deep disturbance layer in the first few seconds of processing. At the same time, the diamond grinding plate is equally effective for hard and soft materials to ensure the consistent grinding effect on the surface of the sample, and there is no uneven between different phases. Can completely eliminate the chamfering phenomenon between the resin and the sample. |

Technical data CAMEO DISK Diamond millill

Product Name | Application | Ø in mm |

CAMEO®Disk Platinium 0 Brun | Grinding hard material (≥ 120 HV) | 200,250,300 |

CAMEO®Disk Platinium 1 Blue | Grinding hard material (≥ 120 HV) | 200,250,300 |

CAMEO®Disk Platinium 2 Green | Grinding hard material (≥ 120 HV) | 200,250,300 |

CAMEO®Disk Platinium 3 Yellow | Grinding hard material (≥ 120 HV) | 200,250,300 |

CAMEO®Disk Platinium 4 Red | Grinding hard material (≥ 120 HV) | 200,250,300 |

Diamond millstone application of small knowledge

Use method of a diamond millstone.

After adsorbing the back of the diamond mill to the FMS magnetic support plate,install it to the aluminum working plate.

Regular maintenance method:in 150 RPM/minute directly to the diamond mill and different grain size of the grinding stone brick,so that the disk again sharp and smooth.

For users who need to use 0,1,2,3,4,it is recommended to use Booster special lubricant instead of water as the grinding plate cooling lubricant.

TOP