clean cut

High elasticity and long service life

Good compatibility, full varieties

Guide for the application of precision cutting wheels

Developed for very fine, precise cuttings the precision cut-off wheels withstand very high demands over a long period of time produce and reduce all subsequent processing steps to a minimum.

clean cut

| Even at the lowest thickness, it can still achieve the transmission of large cut torque, and flat without shaking, so as to accurate positioning, precise cutting. |

High elasticity and long service life

| Due to the use of high grade adhesive, the precision cutting wheel has the characteristics of good elasticity and strong impact resistance, so that it can well respond to the requirements of different knife load required when cutting various materials. The cutting wheel skid and blasting phenomenon is less, and the effective service life is longer. |

Good compatibility, full varieties

| Can be applied in various types of metallographic sample cutting machine, equipped with silicon carbide, alumina (domestic called corundum), diamond material, can adapt to different metallographic sample cutting needs. |

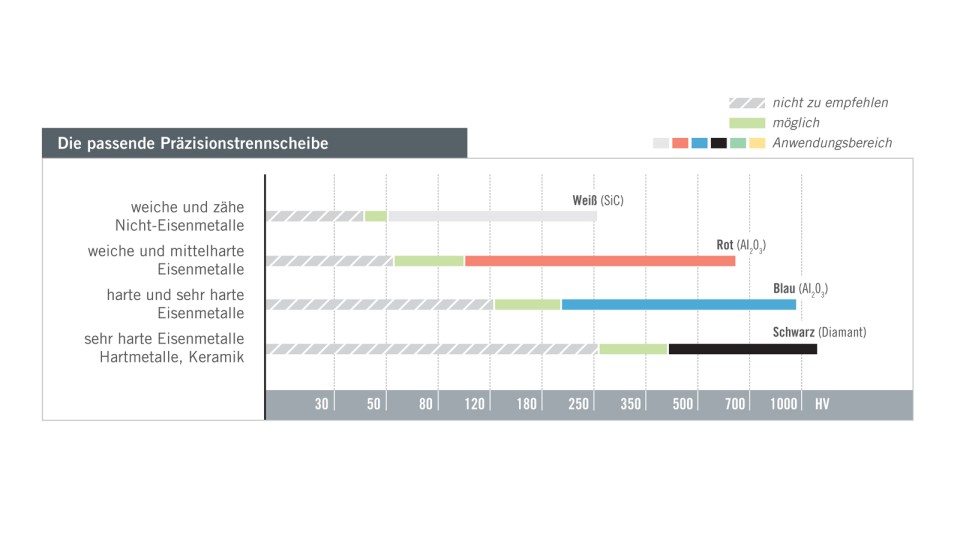

Guide for the application of precision cutting wheels

| Depending on the hardness and abrasive used, the precision cutting wheel comes in four versions: platinum (SiC), red (AI2O3), blue (AI2O3) and black (diamond) and can cut any type of metal material. |

Technical Data Precision Cutting Wheel (10 pieces / box)

Product Name | Type | Dim. (mm) |

Cut-off wheels Red PRECISION (Al2O3) | Soft - semi-hard steel | 125 x 12.7 x 0.45 150 x 12.7 x 0.45 |

Cut-off wheels Blue (PRECISION Al2O3) | Treated metals- special steel | 125 x 12,7 x 0,45 150 x 12,7 x 0,45 203 x 25,4 x 1 |

Cut-off wheels White PRECISION (SIC) | Non ductile material Cast iron Stainless steel | 125 x 12,7 x 0,45 150 x 12,7 x 0,45 203 x 25,4 x 1 250 x 32 x 1,5 305 x 32 x 1,5 |

Cut-off wheels PRECISION DIAMANT | All sintered materials. Ceramic, Cermet, Carbide W and Sic. Glass, silica, quartz. High metal content materials. | 102 x 12,7 x 0,30 127 x 12,7 x 0,40 152 x 12,7 x 0,5 203 x 32 x 0,8 254 x 32 x 1 300 x 32 x 1,3 |

Cutting in the application of small knowledge

1. A larger flange can better support the large cutting wheel to cope with a harder cutting material or reduce the cutting slope of the cutting soft material due to elasticity. Replacing the flange needs to consider the impact on the cutting ability: cutting diameter = (cutter diameter-flange diameter) / 2.

2. Using cutting coolant can effectively reduce the thermal damage and improve the cutting efficiency of cutting: coolant is by adjusting the proportion of water and lubricant to obtain different cooling lubrication ability, adjustable ratio between 1:25 to 1:10, when cutting material soft or heat sensitive material can appropriately increase the proportion of water, to get better cooling effect, when cutting hard material into the knife speed is slow, can increase the proportion of lubricant appropriately to get better lubrication effect.

3. Preparation method of cutting coolant: all the cutting coolant in the market is concentrated, which must be the order of adding water before adding concentrate and stirring evenly. This order determines the suspension structure of water wrapped in oil, so as to effectively adapt to the needs of cooling before lubrication in the cutting process.

TOP